Failure Investigation & Consultancy

With over 25 years’ in the industry and state-of-the-art facilities, our scientists are able to investigate complex issues you are encountering and provide easy-to-read reports to assist in preventing reoccurrence.

Tailored Reporting

Our reports are tailored to the client’s needs. Each report includes short conclusions backed up by data, explanations and photographs to give clarity to often complex issues.

Rapid Service

At SureScreen we pride ourselves on efficient turnaround times. Our clients receive crucial updates on the investigation even before the initial report is sent.

25 Years’ Experience

Our vast experience means we can recommend the best way forward reducing time, costs and unnecessary work.

Failure Investigation

Investigating the modes of failure, degradation, fracture or loss in performance, which ultimately can assist in the identification of the root cause.

Expert Witness

Legal support in the fields of material science and curfew tagging.

Onsite Testing

Site visits for sample recovery, examination and photography as well as appropriate testing to assist with a failure investigation & consultancy.

Reverse Engineering

Conducting appropriate tests and examinations to help determine how components have been manufactured and the materials used in their construction.

Example Report

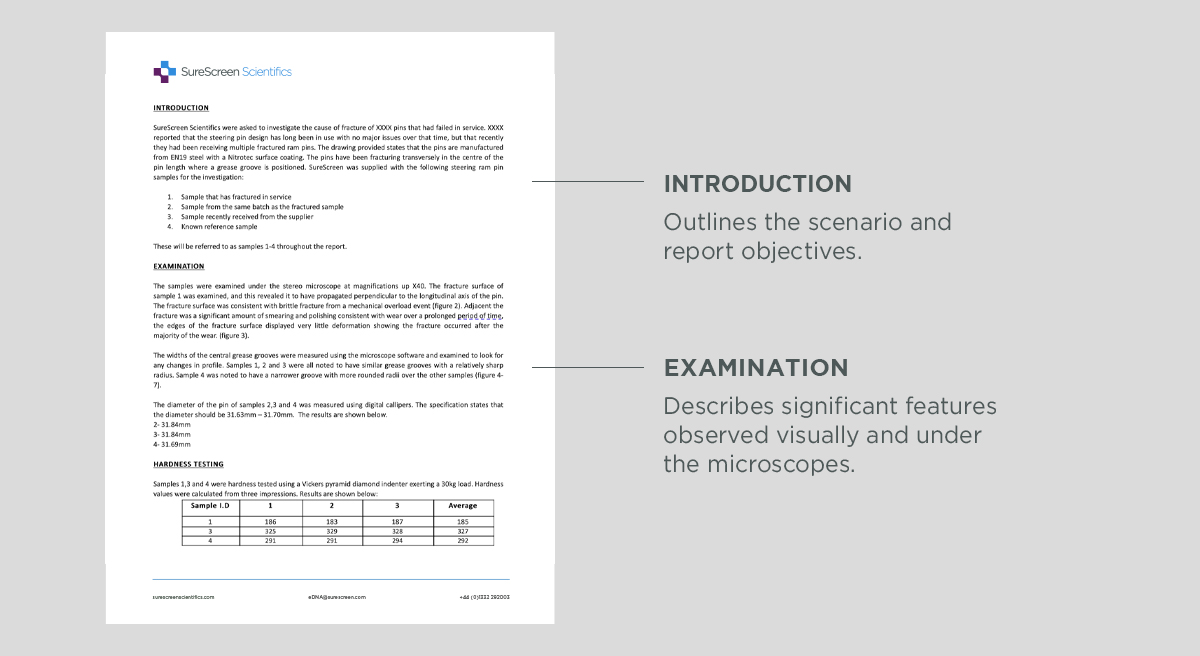

Introduction & Examination

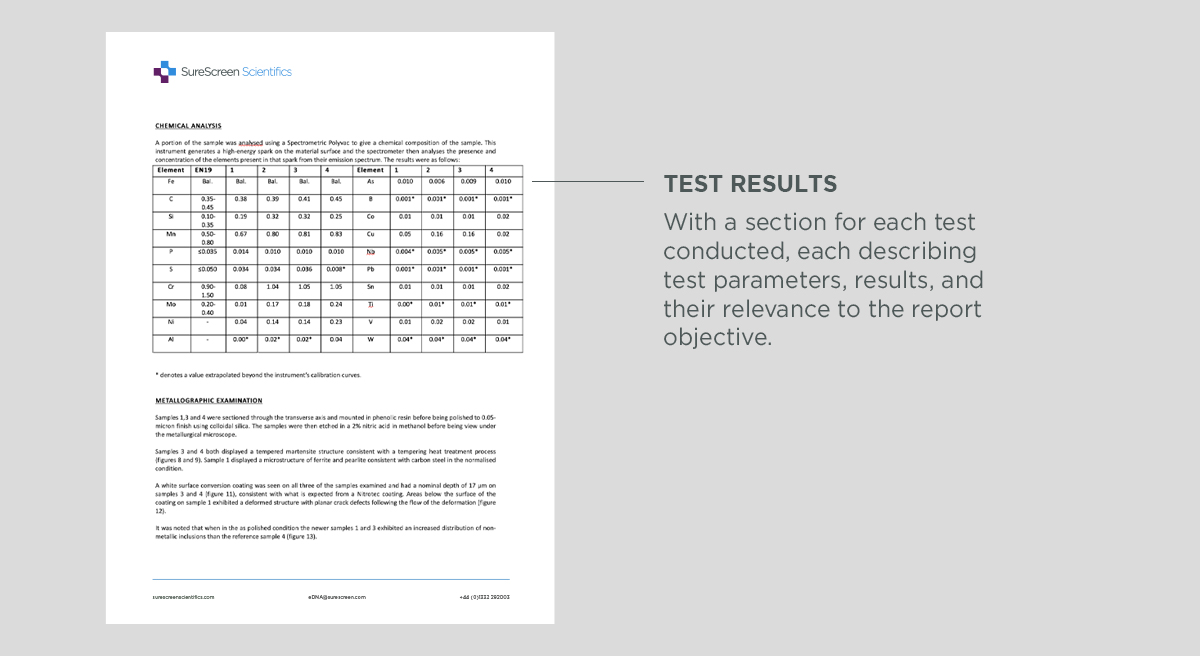

Test Results

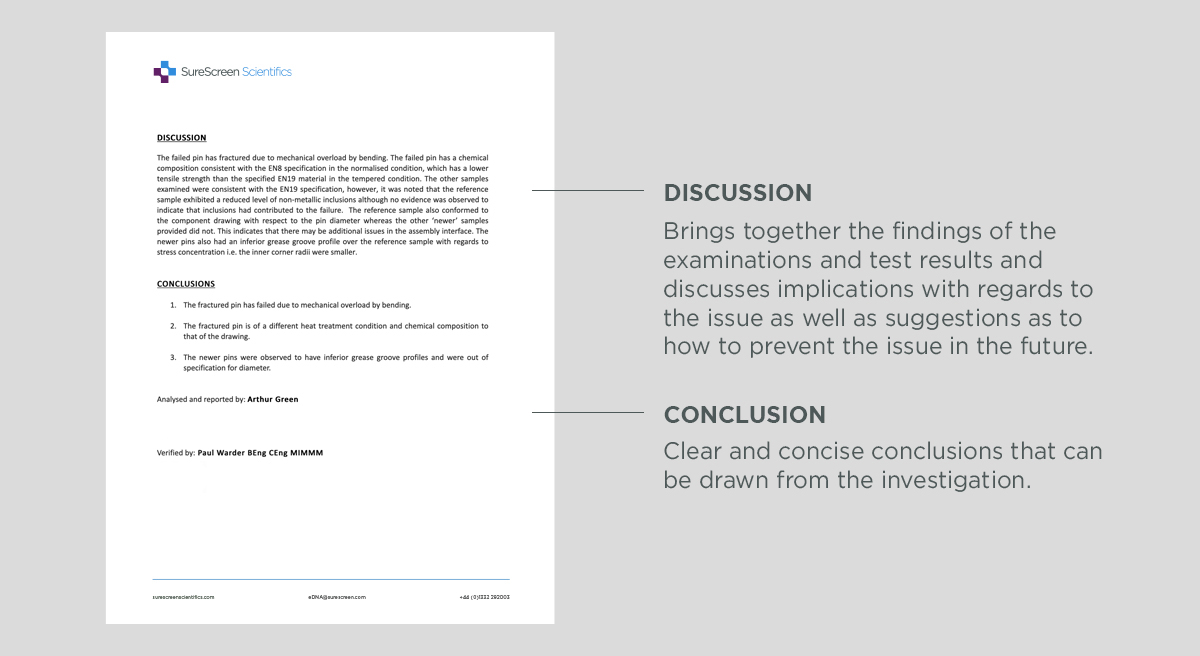

Discussion & Conclusion

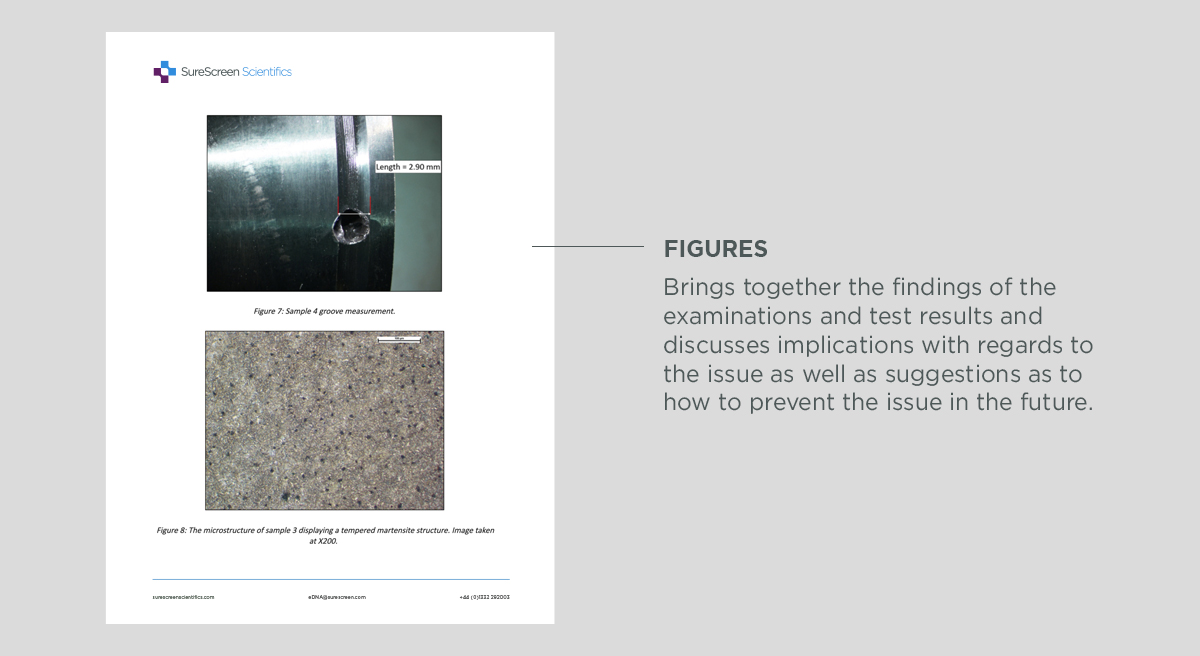

Figures

Case Studies

Arcing Microswitches

The contact surfaces of a microswitch with poor continuity were examined. This revealed a contaminant preventing the surfaces from contacting. Microscopic FTIR analysis of the surfaces revealed the contaminant to be consistent with residual rosin flux.

Bolt Fracture

A bolt was received that had experienced fracture at low load. Metallographic cross-sections through the bolt head revealed a network of branching cracks consistent with stress corrosion cracking (SCC). Chemical analysis of the fracture surfaces using the EDS function of the electron microscope revealed the corrosion to be predominantly from chlorides.

Wire

A portion of wire (2mm x 0.2mm) was discovered in a food product. Examinations and testing included fractography, chemical analysis, metallographic examination and dimensional examination. The information obtained was then compared to a range of possible sources in the factory to help establish the origin.

Turbine Wheel

Examinations of the fracture surfaces revealed the fracture to have occurred due to the presence of an oxide inclusion in the blade. This weakened the cross-section allowing for fatigue cracking propagate. Semi-quantitative chemical analysis of the inclusion indicated it to be refractory material from the casting process.

Library of Failures

See full list hereTorsional Overload of Lifting Chain

Fractured chain used in service to lift a skip used inside a grit-blasting chamber. The chain consisted of 10mm links with a C-hoo...

Stress Corrosion Cracking of a Copper Alloy Component

A copper alloy component had cracked in service and the cracks exhibited a degree of ‘yawning’ (opening) indicative of the pre...

Casting Defect in Copper Alloy

Tapping Tee joints used in water pipe applications had been found to leak from a pin hole defect after installation in service. Th...

Account

Account